Contact:

Amit Bandyopadhyay: amitband@wsu.edu

Susmita Bose: sbose@wsu.edu

School of Mechanical and Materials Engineering

Washington State University, Pullman, WA 99164.

Background

JCDREAM support was utilized to add additive manufacturing capabilities at Washington State University (WSU). WSU has had an additive manufacturing (AM) facility since 1998. Prior to JCDREAM support, WSU’s key AM capabilities included a laser engineered net shaping (LENS) system for metallic materials, an ExOne binder jetting system primarily used for ceramic materials and several fused deposition modeling based AM capability for polymeric materials. With JCDREAM support, both metal and ceramic based AM capabilities have been upgraded. Current capabilities include:

- A directed energy deposition (DED)-based 5-axis metal AM system from Formalloy (CA).

- A laser powder bed metal AM system from 3D Systems (CO).

- A binder jetting AM system from ExOne (PA).

- A Raised 3D FDM system for polymeric materials.

A microwave furnace for densification of ceramic AM parts, and a tabletop CNC for finishing metal AM parts have also been added to the capabilities to complete AM for multi-material structures. All instruments are currently at WSU.

Additive Manufacturing (AM) or Three Dimensional Printing (3DP) is a manufacturing approach where a part can be produced without using any part-specific tooling. Such an approach is ideally suited for manufacturing a small number of parts to validate a design concept or where only a few parts are needed. JCDREAM funding is utilized to establish a state-of-the-art AM laboratory where users can come and get a variety of designs printed using earth-abundant materials such as steels, titanium or different ceramics.

WSU’s AM research facilities can also be used to repair existing metallic parts or add functional coatings on them. These capabilities will be used to innovate some of the next generation multiple-material structures to streamline manufacturing approaches for complex geometries that are difficult to produce otherwise.

DED-based 5-axis AM System

Formalloy’s 5-axis DED system is equipped with a 500 Watt fiber laser, two hoppers for powder feeding and a co-axial powder feeding system. This system was installed in July 2019. Currently located in ETRL 146.

DLaser Powder-bed AM system

3D System’s selective laser melting ProX DMP 200 system. This system was installed in May 2019. Currently located in ETRL 146.

We have already started printing parts using Ti6Al4V powders with different shapes and porosities. Other powders that can be printed are – different steels, Al alloy, Inconel and Ti-alloys.

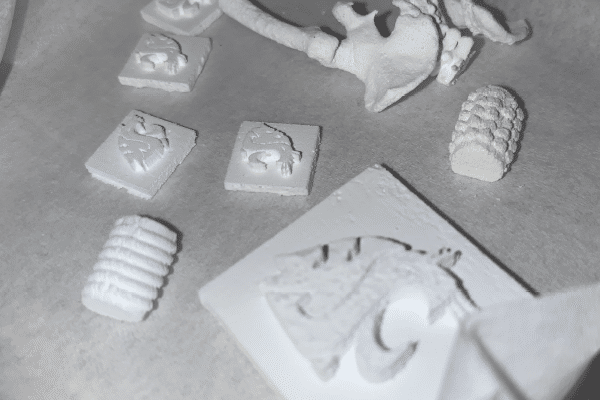

Binder jetting-based AM system

ExOne’s Innovent + binder jetting type AM system that is primarily used for AM of ceramics. This system was installed in March 2019. Currently located in ETRL 343.

We have already started printing parts using calcium phosphate-based ceramic powders using this system. Some complex shaped parts that were printed recently are shown here

FDM AM system from Raised 3D

A multi-purpose polymer-based FDM AM system. This system was installed in February 2019. Currently located in ETRL 142.

Simple and complex shape polymeric (ABS, PLA etc.) materials are currently being printed.

Tormach Multi-purpose CNC System

A multi-purpose tabletop Tormach CNC system. This system was installed in July 2019. Currently located in ETRL 142.