Contact:

Mark Bussell: bussell@wwu.edu

Western Washington University

College of Science & Engineering

Background

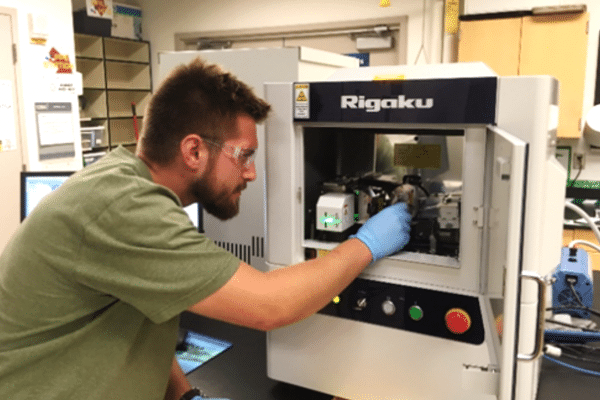

With a $93,000 grant from the Joint Center for Deployment and Research in Earth Abundant Materials (JCDREAM), Western Washington University has purchased and recently installed a Rigaku MiniFlex 6G X-ray diffractometer for the structural analysis of earth-abundant materials. WWU provided $30,000 in matching funds to support the purchase of the MiniFlex 6G diffractometer, which is a tabletop instrument optimized for rapid structural analysis of powdered materials important for clean energy and geologic materials research. The diffractometer uses a beam X-ray to probe the positions of atoms within the structure of crystalline materials, yielding information on the purity, phase composition and crystallite size of a wide range of materials. According to WWU Professor Mark Bussell, the principal investigator on the grant, the MiniFlex 6G diffractometer has dramatically increased the throughput of structural analysis by students and faculty at WWU, as well as community college partners like Whatcom Community College.

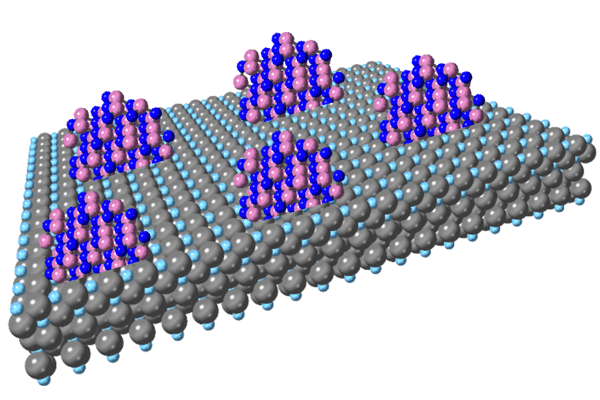

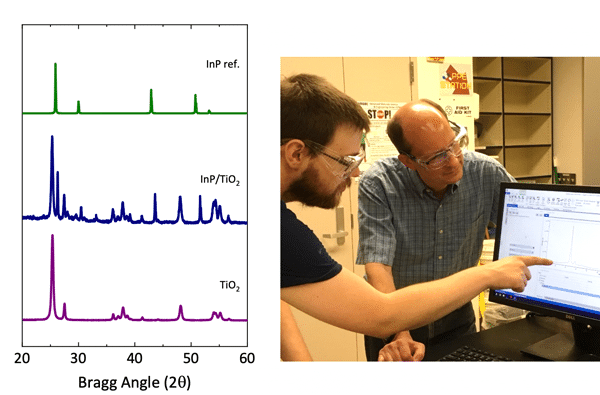

An example research project in which the MiniFlex 6G diffractometer plays a key role is the structural analysis of newly developed photocatalysts for solar fuels production. The photocatalysts, composed of indium and gallium phosphides and oxides, are showing promise for converting carbon dioxide (CO2) to solar fuels such as methanol (CH3OH) under simulated sunlight without the use of precious metals such as platinum or palladium. One photocatalyst formulation under investigation In Professor Bussell’s laboratory consists of indium phosphide (InP) nanoparticles anchored onto titanium dioxide (TiO2) as shown schematically in Figure 2. X-ray diffraction analysis of the InP/TiO2 photocatalyst (Figure 3) confirms the crystalline nature and phase purity of the InP and TiO2 components and allows determination of the InP crystallite size to be 22 nanometers in diameter.

The MiniFlex 6G X-ray diffractometer is currently being used by 12 different users in 7 research groups at WWU as well as one lab group from Whatcom Community College. In addition to its use in research, the X-ray diffractometer will be used in laboratory courses at WWU and Whatcom CC starting in Fall 2019 with remote usage by students at Peninsula College in the planning stages.

Top Left: Figure 1. WWU M.S. student Daniel Korus loading a sample of CuInS2/ZnS core-shell quantum dots into the Rigaku MiniFlex 6G X-ray diffractometer.

Top Right: Figure 2.Schematic representation of an InP/TiO2 photocatalyst composed of InP nanoparticles anchored to a TiO2 support material.

Bottom Left: Figure 3. (Left) X-ray diffraction pattern of an InP/TiO2 photocatalyst along with reference patterns for InP and the TiO2 support material. (Right) WWU Professor Mark Bussell and Whatcom Community College student Sam Baldwin analyzing the X-ray diffraction pattern of a nanocrystalline TiO2 support material.